How to use Expando expansive mortar

Here is all the technical information you need to know before using Expando.

Technical Information

EXPANDO is a non-explosive, non-toxic chemical demolition agent that safely and silently cracks rocks and concrete in four easy steps: Drill, Mix, Pour and Expand!

Preparation before using Expando

First measure the temperature of the job site, demolition agent, water, stone/concrete and container to ensure temperatures are in accordance with compliance requirements. Next, select the correct Expando product range for the job site temperature.

You will need to prepare the following things:

- Demolition agent

- Clean and cold water

- Plastic or metal bucket

- Beater or wooden rod for mixing

- Safety goggles

- Rubber gloves

- Dust proof mask (recommended)

- Helmet (recommended)

- Thermometer (recommended)

Step 1. Drill

Drill holes in the rock or concrete where the material is to be cracked.

The distance between holes will vary depending on type of material. Generally, the closer the holes, the quicker it is to crack the material.

The diameter of the holes will dictate cracking results – holes that are too small may result in sub-optimal performance, while holes that are too big may cause blowout shots.

Please note: do not exceed 40mm diameter drill size

The following figures are for reference purposes only. For best results, it is advisable to carry out experiments or tests with Expando before starting work.

Holes should be cleaned out using compressed air or vacuum.

Step 2. Mix

Expando expansive mortar must be thoroughly mixed with clean cold water before use. Gradually add one bag of Expando to 1.5 – 1.7 litres of water. Stir until you obtain a smooth lump-free slurry.

Use only open buckets or containers for mixing. Do not use narrow-necked containers.

Avoid adding extra water, as this may reduce the concentration and effectiveness of the mix.

Avoid mixing more than 10kg of Expando at any one time.

Step 3. Pour

Pour the freshly mixed slurry into pre-drilled holes within 10 minutes of mixing. Do not look directly into the filled holes for the next 2 – 6 hours.

Tamp the mortar filled into the holes by using a slightly smaller stamp stem. For long holes, tamp the mortar section by section to remove trapped air pockets.

For horizontal and slant holes, insert a slightly smaller plastic pipe into the hole and fill the mortar into the pipe slowly, withdrawing the pipe from the hole simultaneously. Tamp the mortar section by section to remove trapped air pockets.

Another method for horizontal holes is to fill sausage shaped plastic bags. Tie the bags off and insert them into the horizontal holes.

The benefit of this method is that it will retain the fluid in the horizontal hole.

Step 4. Expand

EXPANDO’s reaction time to crack stones varies from 24 to 76 hours.

This varies depending on the material being cracked, the hole design and the ambient temperature at the job site. Expando continues to increase in pressure for up to 5 days.

Caution: The chemical reaction of Expando and water generates heat. If the reaction goes too quickly the temperature can be above the boiling point of water before all the water has chemically combined with Expando. This can result in a steam driven explosion which blows the Expando mortar from the holes with sudden force.

Expando, once mixed and poured into holes, expands as it slowly sets, gradually applying expansive stress up to 14,000 PSI.

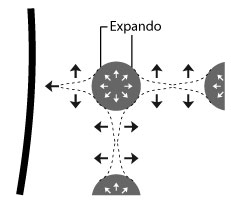

Initially propagation occurs, then the crack widens. When multiple holes are filled adjacent to each other, the cracks propagate to join with the neighbouring holes. This allows you to determine the exact direction of the cracks with your hole pattern designs.

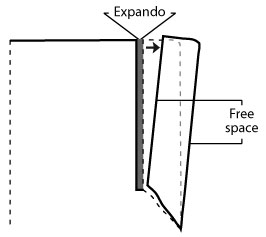

The hole pattern design must allow the material to move to free space when Expando expands as shown in the diagrams below. Failure to provide free space will result in unpredictable material movement. We recommend that you plan your work so you are always working away from a free space (this gives the broken piece of material somewhere to move to).

How to prevent expansive mortar blowout shoots

Although it’s highly unlikely, EXPANDO might blow out from the filled holes if you have not followed these instructions correctly:

- Use the right type of EXPANDO according to the temperature.

- It is unsafe to drill more than a 40mm diameter hole size, in doing so you may incur a blowout.

- 28mm is the minimum hole size you should drill in any material.

- Too shallow holes may result in blowout. (Depth must be four times longer than its diameter or more).

- Lots of dry dust in holes will absorb water from EXPANDO and result in a blowout.

- Use enough water and mix thoroughly to avoid lump formation.

- Do not manually mix more than 10kg (2 bags) for each lot.

- Pour the mixture into holes within 10 minutes after mixing.

- Do not overfill the holes.

- Do not plug filled holes with bars or similar tools.

Available Types of Expando

The chemical reaction of Expando depends on the temperature of the breaking object.

- SCA I 20°C – 35°C

- SCA II 10°C – 25°

- SCA III 0°C – 15°

The reaction time of Expando to crack stone varies from 24 hours to 72 hours, depending on the cracking object, material, hole design and temperature. Generally speaking, within the temperature scope of each type, the higher the temperature of the object and the closer together the holes, the quicker the object will crack (otherwise, the opposite will occur).

Additional technical support

For more technical advice or support, contact our support hotline directly on 0402 759 895 or email info@expando.com.au

See also: